Unlock Savings: Mastering Procurement Process Improvement

In today's dynamic business landscape, the pursuit of efficiency and cost-effectiveness is paramount. One area often overlooked, yet ripe with potential for significant gains, is the procurement function. Procurement process improvement isn't just about cutting costs; it's a strategic imperative that can redefine an organization's competitive edge, enhance resilience, and foster stronger, more reliable supply chains.

From sourcing raw materials to acquiring essential services, every step in the procurement journey presents an opportunity for optimization. This comprehensive guide will delve into actionable strategies for procurement process improvement, exploring how to streamline operations, leverage cutting-edge technology, build robust supplier relationships, and cultivate a culture of continuous enhancement to deliver substantial value to your organization.

Table of Contents

- What is Procurement Process Improvement?

- The Eight Essential Stages of an Effective Procurement Process

- Why Procurement Process Improvement is Crucial for Modern Businesses

- Key Strategies for Enhancing Procurement Efficiency

- Practical Steps for Implementing Procurement Process Improvements

- Measuring Success: Tracking Performance and ROI

- Overcoming Challenges in Procurement Improvement

- The Future of Procurement: Strategic Advantage

What is Procurement Process Improvement?

At its core, the procurement process is a structured method of acquiring goods and services needed for an organization to function. It encompasses the entire series of processes essential to get products or services from requisition to purchase order and invoice approval. Procurement process improvement refers to the systematic effort to identify, analyze, plan, implement, and monitor changes within these processes to enhance their effectiveness, efficiency, and overall value delivery. It's about refining your buying strategy to ensure budget adherence, evaluate suppliers rigorously, and manage orders seamlessly.

- Jessica Sodi Age

- Mike Beltran Height And Weight

- Is Dr David Jeremiah Still Alive

- Professional Candid Photography

- Karen Grassel

The goal is not merely to cut costs, though that is a significant benefit. It's also about enhancing efficiency, reducing risks, improving supplier relationships, ensuring compliance, and ultimately, driving better results for the entire organization. This involves a holistic approach, looking at every touchpoint from initial need identification to final payment, seeking opportunities to streamline operations, harness digital tools, and adopt sustainable practices for strategic advantage.

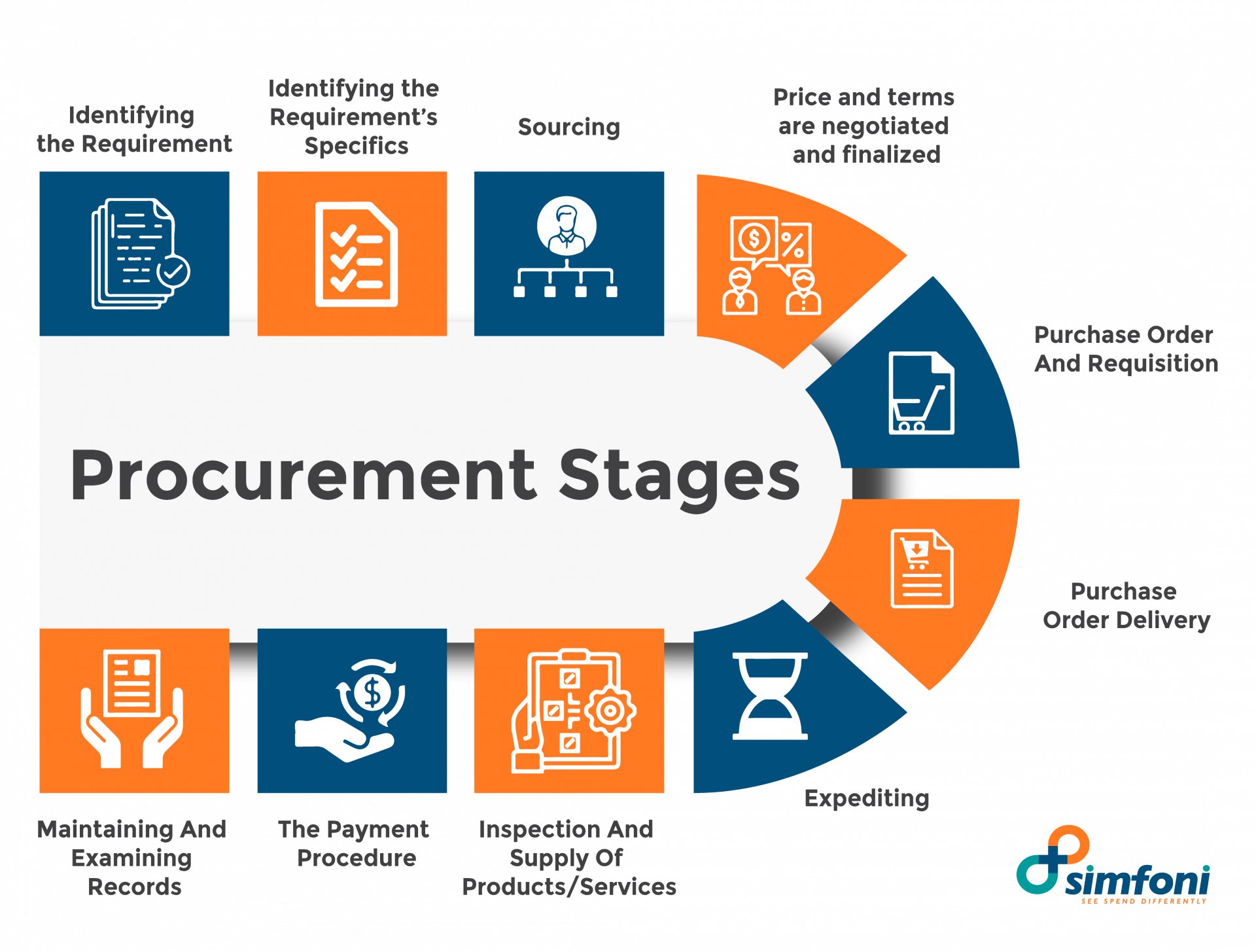

The Eight Essential Stages of an Effective Procurement Process

Understanding the fundamental stages of procurement is the first step toward effective procurement process improvement. While specific terminology may vary, most robust procurement cycles include these key phases:

- Need Recognition: The internal department identifies a need for goods or services.

- Purchase Requisition: A formal request is submitted, detailing the required items, quantity, and justification.

- Review and Approval: The requisition is reviewed by relevant stakeholders and approved based on budget and policy.

- Sourcing and Supplier Selection: Potential suppliers are identified, evaluated (based on criteria like quality, price, reliability, and sustainability), and a shortlist is created. This stage is crucial for developing strong supplier relationships from the outset.

- Negotiation and Contracting: Terms, conditions, and pricing are negotiated, leading to a formal contract or purchase order.

- Order Management: The purchase order is issued, and the order is tracked through fulfillment, shipping, and delivery.

- Goods Receipt and Inspection: Received goods are inspected for quality and quantity against the purchase order.

- Invoice Processing and Payment: The invoice is verified against the purchase order and goods receipt, and payment is processed.

The right technology can significantly improve each of these steps, transforming what can be a cumbersome manual process into a streamlined, automated workflow. By enhancing procurement efficiency through optimizing these processes, organizations can realize substantial benefits.

- Thamiko Fatu Dad

- Esli Monkey App Leak

- Where Is Iran Located In The World

- Qualls

- Karen Carpenters Final Words

Why Procurement Process Improvement is Crucial for Modern Businesses

Improving procurement performance is crucial for organizations looking to streamline their operations, reduce costs, and enhance overall efficiency. In today's competitive and often volatile market, businesses face constant pressure to optimize every facet of their operations. The procurement function, being a significant cost center and a critical enabler of operations, offers immense potential for value creation. Practical ways procurement leaders can improve the procurement process, increase cost savings, and deliver value to their organizations include focusing on strategic sourcing, automation, and supplier collaboration.

The benefits of improving procurement processes range from significant cost savings and increased operational efficiency to better supplier relationships and improved quality control. For instance, a well-optimized procurement process can reduce maverick spending, ensure better contract compliance, and mitigate supply chain risks. Moreover, in a world increasingly focused on sustainability and ethical sourcing, a robust procurement process allows companies to ensure their supply chain aligns with their corporate social responsibility goals. Discover key procurement process improvements to enhance sourcing efficiency, reduce costs, and drive better results in 2025.

Key Strategies for Enhancing Procurement Efficiency

To achieve meaningful procurement process improvement, organizations must adopt a multi-faceted approach. By implementing strategic changes, companies can achieve significant improvements in their procurement processes.

Leveraging Technology and Digital Tools

The digital transformation has revolutionized procurement. Streamlining operations and harnessing digital tools are no longer optional but essential for strategic advantage. Modern procurement software, often referred to as e-procurement or procure-to-pay (P2P) solutions, can automate many manual tasks, reduce errors, and provide real-time insights. These tools can:

- Automate Requisition and Approval Workflows: Speed up the initial stages, reducing bottlenecks and ensuring compliance.

- Centralize Supplier Information: Create a single source of truth for supplier data, making evaluation and selection more efficient.

- Enable E-Sourcing and E-Auctions: Facilitate competitive bidding and negotiations, leading to better pricing and terms.

- Streamline Purchase Order Generation: Automate PO creation and dispatch, reducing manual effort.

- Automate Invoice Processing: Implement three-way matching (PO, receipt, invoice) to accelerate payment cycles and reduce discrepancies.

- Provide Data Analytics: Offer dashboards and reports on spending patterns, supplier performance, and process bottlenecks, crucial for continuous improvement.

According to industry reports, companies that fully embrace digital procurement solutions can see up to a 15-20% reduction in procurement costs and a significant decrease in processing times. This technological leap is a cornerstone of modern procurement process improvement.

Optimizing Processes and Lean Principles

Beyond technology, the underlying processes themselves need optimization. This involves adopting lean procurement principles, which focus on eliminating waste, reducing lead times, and maximizing value. How to characterize lean procurement? It's about identifying and removing non-value-adding activities from the entire procure-to-pay cycle. Practical ways to achieve this include:

- Process Mapping: Visually map out current procurement processes to identify inefficiencies, redundancies, and bottlenecks.

- Standardization: Standardize forms, templates, and procedures to ensure consistency and reduce errors.

- Simplification: Simplify complex steps, consolidate orders where possible, and reduce the number of approval layers.

- Demand Management: Implement better planning and forecasting to reduce urgent, high-cost purchases.

- Supplier Rationalization: Optimize your supplier base, consolidating spend with fewer, more strategic partners to gain leverage and simplify management.

By diving deep into the procurement process and applying these principles, organizations can significantly boost efficiency, reduce costs, and streamline operations for better business performance.

Building Strong Supplier Relationships

Developing strong supplier relationships is essential for long-term success in procurement. It goes beyond transactional interactions and moves towards collaborative partnerships. When suppliers are viewed as strategic partners, it can lead to:

- Improved Quality and Innovation: Suppliers are more likely to share innovations and work collaboratively on quality improvements.

- Better Pricing and Terms: Long-term relationships can lead to more favorable pricing, flexible payment terms, and priority service.

- Enhanced Supply Chain Resilience: Trusted suppliers are more likely to support you during disruptions, offering alternative solutions or prioritizing your orders.

- Risk Mitigation: Collaborative relationships allow for shared understanding and proactive management of risks.

Effective supplier relationship management (SRM) involves regular communication, performance reviews, joint problem-solving, and shared goals. It's a critical component of any comprehensive procurement process improvement strategy.

Implementing Continuous Improvement

In the current business landscape, continuous improvement is vital to stay ahead. Procurement is not a static function; it must evolve with market changes, technological advancements, and business needs. Taking a continuous improvement approach to procurement ensures that processes, strategies, and technologies evolve and adapt to changing market and business needs. This involves:

- Regular Performance Reviews: Consistently track key performance indicators (KPIs) to identify areas for further optimization.

- Feedback Loops: Establish mechanisms for internal stakeholders and suppliers to provide feedback on procurement processes.

- Benchmarking: Compare your procurement performance against industry best practices and competitors.

- Pilot Programs: Test new technologies or process changes on a small scale before full implementation.

- Training and Development: Invest in the skills and knowledge of your procurement team to keep them abreast of new tools and methodologies.

Efficiently identify, analyze, plan, implement, and monitor for continuous improvement. This iterative cycle ensures that procurement remains agile and responsive, consistently seeking ways to enhance supply chain resilience, reduce risks, and drive strategic success.

Practical Steps for Implementing Procurement Process Improvements

Embarking on a procurement process improvement journey requires a structured approach. Here's a practical checklist to guide you:

- Assess Current State: Begin by thoroughly documenting your existing procurement processes. Identify pain points, bottlenecks, and areas of inefficiency. Gather data on spend, cycle times, and supplier performance.

- Define Goals: Clearly articulate what you want to achieve. Do you aim to reduce costs by a certain percentage? Shorten lead times? Improve supplier satisfaction? Specific, measurable, achievable, relevant, and time-bound (SMART) goals are essential.

- Form a Cross-Functional Team: Procurement process improvement is not solely a procurement department's responsibility. Involve stakeholders from finance, operations, legal, and relevant business units to ensure buy-in and comprehensive perspectives.

- Prioritize Initiatives: Based on your assessment and goals, prioritize the improvements that will yield the greatest impact with the least effort initially. This allows for quick wins and builds momentum.

- Select Technology (if applicable): Research and select procurement software that aligns with your needs and budget. Ensure it integrates with existing systems.

- Develop New Processes: Design optimized workflows, leveraging technology and lean principles. Create detailed process maps for the "to-be" state.

- Pilot and Test: Before a full rollout, test new processes or technologies in a controlled environment. Gather feedback and make necessary adjustments.

- Implement and Train: Roll out the improved processes across the organization. Provide comprehensive training to all users to ensure smooth adoption.

- Communicate Changes: Clearly communicate the reasons for the changes, the benefits, and the new procedures to all affected parties.

- Monitor and Measure: Continuously track performance against your defined KPIs. Use data to identify areas for further refinement.

Enhance your procurement process with these actionable steps. Optimize your procurement strategy with these 10 best practices to learn how to enhance cost savings, supplier relationships, and efficiency while ensuring compliance.

Measuring Success: Tracking Performance and ROI

To truly understand the impact of procurement process improvement, robust measurement is non-negotiable. It's not enough to implement changes; you must track their effects. Key Performance Indicators (KPIs) are vital for this. Some essential KPIs include:

- Cost Savings: Track direct savings from negotiated prices, reduced maverick spending, and process efficiencies.

- Cycle Time: Measure the time from requisition to purchase order issuance and from invoice receipt to payment. Shorter cycles indicate greater efficiency.

- Compliance Rate: Monitor adherence to contracts, policies, and regulatory requirements.

- Supplier Performance: Assess on-time delivery, quality, and responsiveness.

- Process Efficiency: Track the number of manual interventions, errors, and reworks.

- Return on Investment (ROI): Calculate the financial return on investments made in technology and process changes.

Regular reporting and analysis of these metrics allow procurement leaders to demonstrate the value delivered to their organizations and identify areas for further refinement. This data-driven approach is fundamental to sustaining procurement process improvement over time.

Overcoming Challenges in Procurement Improvement

While the benefits of improving procurement processes are clear, the challenges of procurement improvement cannot be underestimated. Implementing significant changes within an organization often encounters resistance. Common hurdles include:

- Resistance to Change: Employees may be comfortable with existing processes, even if they are inefficient. Overcoming this requires strong leadership, clear communication, and adequate training.

- Lack of Data Visibility: Without proper systems, it can be difficult to gather accurate data on spending, supplier performance, and process bottlenecks.

- Integration Issues: New procurement software may not seamlessly integrate with existing ERP or financial systems, leading to data silos and manual workarounds.

- Supplier Reluctance: Some suppliers may be resistant to adopting new digital platforms or changing established ways of working.

- Insufficient Resources: A lack of dedicated personnel, budget, or time can hinder improvement initiatives.

- Complex Legacy Systems: Older, entrenched systems can be difficult and costly to replace or upgrade.

Addressing these challenges requires a strategic approach, starting with a clear change management plan, investing in robust technology, and fostering a culture of collaboration and continuous learning. It's about recognizing that improvement is a journey, not a destination.

The Future of Procurement: Strategic Advantage

As we look towards 2025 and beyond, the role of procurement will continue to evolve from a transactional function to a strategic driver of business value. Boost efficiency with 2025 procurement process improvement by focusing on innovation, sustainability, and resilience. Future-forward procurement organizations will:

- Embrace AI and Machine Learning: For predictive analytics, demand forecasting, automated sourcing, and risk management.

- Prioritize Sustainability: Integrate environmental, social, and governance (ESG) criteria into supplier selection and performance monitoring.

- Enhance Supply Chain Resilience: Diversify supply bases, implement robust risk management strategies, and leverage real-time visibility tools.

- Become a Strategic Partner: Collaborate even more closely with internal stakeholders and external suppliers to drive innovation and achieve broader business objectives.

- Focus on Talent Development: Invest in upskilling procurement professionals to manage complex technologies and strategic relationships.

By continuously refining their buying strategy, ensuring budget adherence, evaluating suppliers meticulously, and managing orders with precision, organizations can position procurement as a source of competitive advantage. This strategic evolution of procurement ensures it remains a vital function for any business that wants to remain competitive in the market.

Conclusion

Procurement improvement is a necessary process for any business that wants to remain competitive in the market. We've explored actionable strategies for procurement process improvement to reduce costs, enhance efficiency, and build better supplier relationships. From understanding the eight essential stages of an effective procurement process to leveraging technology, optimizing processes, and nurturing strong supplier partnerships, the path to a more efficient and strategic procurement function is clear.

The benefits of improving procurement processes range from significant cost savings and increased efficiency to better supplier relationships and improved quality control. By implementing the six strategies discussed in this article – leveraging technology, optimizing processes, building strong supplier relationships, implementing continuous improvement, and adopting a data-driven approach – companies can achieve remarkable transformations. We've also touched upon the practical steps and the challenges involved, emphasizing that a continuous improvement approach to procurement ensures that processes, strategies, and technologies evolve and adapt to changing market and business needs. Take the first step towards a more optimized, resilient, and value-driven procurement operation today. Share your thoughts or challenges in the comments below, or explore our other articles on supply chain optimization for more insights!

️ Procurement 101 - How to Optimize Procurement Process Flow?

![What is eProcurement - A Guide To Digital Procurement Processes [2023]](https://simfoni.com/wp-content/uploads/2022/06/What-is-eProcurement1.png)

What is eProcurement - A Guide To Digital Procurement Processes [2023]

![What is Procurement Management & What are the Benefits? [2022]](https://simfoni.com/wp-content/uploads/2022/01/Steps-involved-in-Procurement-Management-Process.png)

What is Procurement Management & What are the Benefits? [2022]