The Enduring Heat: Unveiling Copper's Melting Point

Copper, a metal revered since ancient times, plays an indispensable role in modern society, from the intricate wiring in our homes to the robust components in industrial machinery. Its widespread utility is largely attributed to a unique combination of properties, chief among them being its excellent electrical and thermal conductivity, good ductility, and notable corrosion resistance. Yet, for engineers, metallurgists, and enthusiasts alike, understanding a fundamental characteristic—the copper melting point—is paramount. This specific temperature dictates how copper behaves under extreme heat, influencing everything from its processing and recycling to its application in high-temperature environments.

Delving into the precise temperature at which copper transitions from a solid to a liquid state reveals critical insights into its material science. This article aims to provide a comprehensive exploration of the copper melting point, examining its exact values, the factors that can influence it, and its profound implications across various industries. We will compare it with other common metals and offer essential safety tips for handling this versatile material in its molten form, ensuring a thorough understanding of why this specific thermal threshold is so vital.

Table of Contents

- Understanding the Essence of Melting Point

- The Precise Melting Point of Pure Copper

- Copper: A Profile of a Remarkable Metal

- Factors Influencing Copper's Melting Point

- Copper's High Melting Point in Industrial Applications

- Comparing Copper's Melting Point with Other Metals

- Safety First: Working with Molten Copper

- Conclusion: The Unyielding Nature of Copper

Understanding the Essence of Melting Point

At its core, the concept of a melting point is fundamental to material science. In general, melting is a phase change of a substance from the solid to the liquid phase. It represents the specific temperature at which a substance transitions from a rigid, fixed structure to a fluid state. More precisely, the melting point is the temperature at which a substance changes from solid to liquid state. This critical thermal threshold is not merely an academic value; it's a defining characteristic that dictates a material's behavior under heat, its processing requirements, and its suitability for various applications. For metals like copper, understanding this point is crucial for everything from casting and welding to designing electrical components that operate under varying thermal loads. It signifies the point where the kinetic energy of the atoms within the solid lattice becomes sufficient to overcome the intermolecular forces holding them in a fixed position, allowing them to move freely as a liquid.

- Lily Phillips World Record Video

- Spotsnews 05custom Udon Secrets Pixiv Finds A Delicious Dive

- Peter Ellis Kings Guard

- Katrina Sloane

- Florinda Meza

The Precise Melting Point of Pure Copper

When discussing the copper melting point, it's important to be precise, as minor variations can be noted depending on the source and measurement conditions. However, a widely accepted and frequently cited value for pure copper is 1084 °C (Celsius), which translates to 1983 °F (Fahrenheit) at standard pressure. This figure serves as a benchmark for the element. Some references might provide slightly more granular data, such as the melting point of copper being 1084.62°C, further emphasizing the precision involved in material science.

It's also common to see the melting point of pure copper cited as 1085°C, or approximately 1084°C (1984°F). These slight differences often arise from rounding or specific experimental conditions, but they all cluster around the same critical temperature. It's vital to note that these points are associated with standard atmospheric pressure. Deviations from this pressure can influence the melting temperature, a factor we will explore later.

An interesting practical consideration arises when dealing with recycled materials: what is the melting point of copper scrap? The good news is that the melting point of copper scrap is essentially the same as that of pure copper, which is approximately 1084°C (1984°F). While the presence of impurities in scrap copper can affect the melting process itself, potentially requiring more energy or altering the flow characteristics, it does not significantly change the fundamental melting point of the copper itself. This consistency is beneficial for recycling efforts, allowing scrap to be re-melted and reused without drastically different thermal requirements.

- Martin Henderson Wife

- Tim Miller Husband Photo

- Lyde Allen Green

- Aishah Sofey Erome The Rising Star In The Digital Age

- Calico Cat

Copper: A Profile of a Remarkable Metal

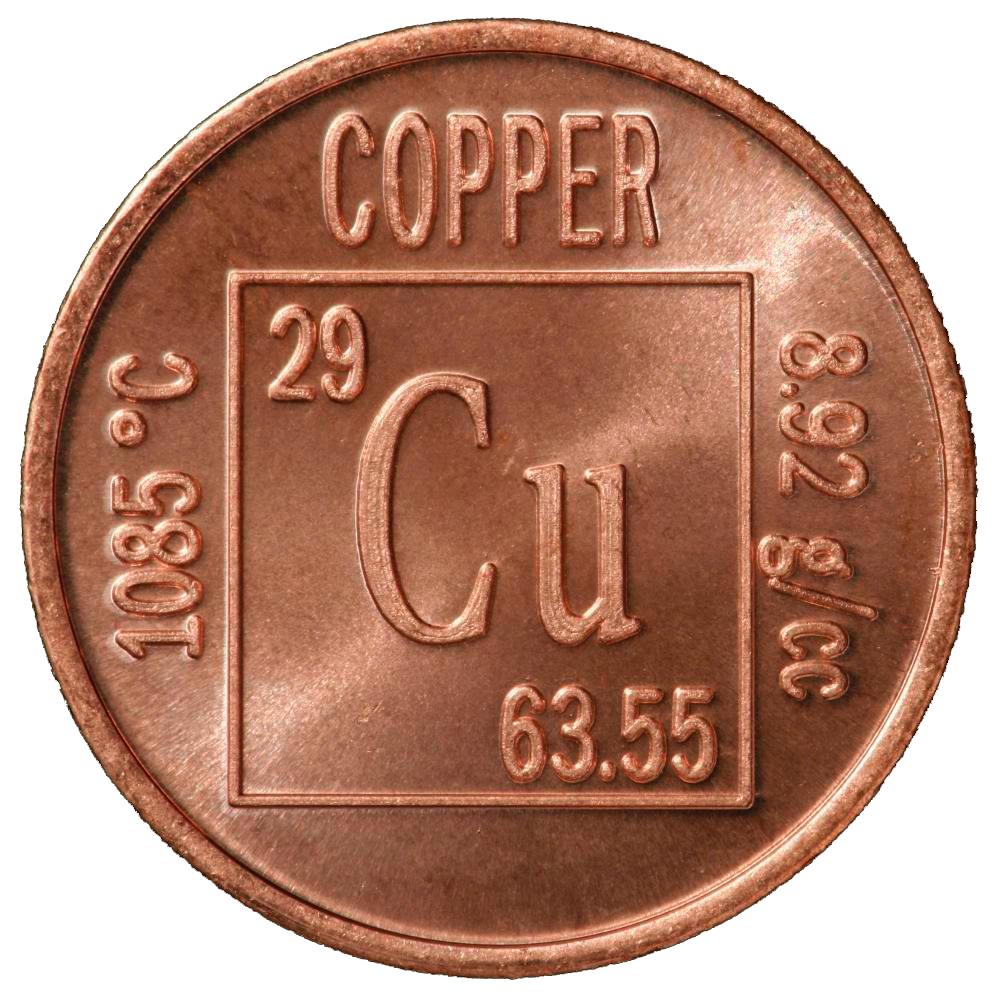

Before diving deeper into its thermal properties, it's worth appreciating copper as an element. Copper is a chemical element with the symbol Cu (from the Latin "cuprum") and atomic number 29. It's a naturally occurring metal with a distinctive reddish color and takes on a bright metallic luster. Beyond its aesthetic appeal, copper is a tough metal with a moderately high melting point, making it suitable for a wide array of demanding applications.

Its physical characteristics are truly impressive. Copper is an excellent conductor of heat and of electricity, finding extensive use as an electric conductor. In fact, it is second only to silver as an electrical conductor, making it the material of choice for most electrical wiring and components due to its superior cost-effectiveness. Pure copper is soft and can be drawn into wire or hammered into desired shapes, a property known as ductility and malleability, respectively. This allows for intricate designs and flexible applications. Additionally, copper boasts good corrosion resistance, contributing to its longevity in various environments. The thermal conductivity of copper is notably high at 401 W/(m·K), further underscoring its efficiency in heat transfer applications. For a complete and detailed technical data about the element copper in the periodic table, its properties are consistently remarkable.

Copper's Boiling Point vs. Melting Point

While the melting point signifies the transition from solid to liquid, it's important not to confuse it with the boiling point. Is copper melting point or boiling point the higher temperature? The boiling point of copper is significantly higher than its melting point. Specifically, the boiling point of copper is 2562°C, or more precisely, 2590 degrees Celsius, which is substantially higher than its melting point at 1084 degrees Celsius. This vast difference is due to the fact that copper has a high specific heat capacity, meaning it requires a considerable amount of energy to raise its temperature and, subsequently, to transition from a liquid to a gaseous state. This high boiling point further contributes to copper's utility in high-temperature applications where it needs to remain in a liquid state for processing without vaporizing too readily.

Factors Influencing Copper's Melting Point

While the melting point of pure copper at standard pressure is a fixed value, several factors can influence the observed melting behavior and the precise temperature at which a copper-based material liquefies. Understanding these factors is crucial for precise material processing and application.

Alloy Composition and Impurities

One of the most significant factors affecting copper’s melting point is its composition. The melting point of copper varies depending on the type of copper alloy, crystal structure, and impurities present. Pure copper has a melting point of 1085°C (or 1984°F), but when other elements are introduced to form an alloy, this temperature can change considerably.

Learn about the melting point of pure copper and its alloys, and how it affects various applications and processes. For instance, brass (an alloy of copper and zinc) and bronze (an alloy of copper and tin) will have different melting points than pure copper. The presence of alloying elements alters the atomic bonding within the material, which in turn affects the energy required to break these bonds and transition to a liquid state. This is why the hardness and melting point of the resulting alloys are distinct from those of the base metal. Similarly, even small amounts of impurities in scrap copper can affect the melting process, though as noted earlier, they do not significantly change the melting point itself, but rather the overall melting behavior and quality of the molten metal. This understanding is critical for controlling the properties of engineered copper-based materials.

Environmental Conditions: Pressure and Altitude

Beyond material composition, environmental conditions, particularly pressure and altitude, also play a role in the evaluation of copper melting point. The melting point (or, rarely, liquefaction point) of metals is typically defined at atmospheric pressure. However, deviations from this standard can influence the temperature at which phase change occurs.

For instance, as you move to a high altitude, the melting point of copper reduces. This is because atmospheric pressure decreases at higher altitudes. Lower pressure means less external force is imposed on the material, making it slightly easier for the atoms to break free from their solid lattice structure and transition into a liquid state at a marginally lower temperature. Conversely, in high pressure, the heat required for melting copper is high as more heat is imposed. Increased pressure effectively "pushes" the atoms closer together, requiring more energy (and thus a higher temperature) to overcome these forces and initiate melting. Therefore, when evaluating copper melting point, you must consider the environment, as variations in pressure can subtly but measurably alter the exact temperature threshold.

Copper's High Melting Point in Industrial Applications

Copper's moderately high melting point is not just a scientific curiosity; it's a critical property that underpins its utility in countless industrial applications. Learn why copper melts at 1084°C (1983°F) and how it is used in various industries. This elevated temperature threshold makes copper an ideal material for processes that involve significant heat.

Find out how copper's high melting point makes it useful in welding, metal melting, and alloy production. In welding, for example, copper electrodes are often used due to their ability to withstand the intense heat generated during the process without deforming or melting prematurely. Its high thermal conductivity also helps dissipate heat away from the weld zone, contributing to a stable and efficient operation. In metal melting operations, copper crucibles or molds are sometimes employed because they can contain molten metals with lower melting points without themselves liquefying.

Furthermore, in alloy production, the high copper melting point allows it to be combined with other metals at elevated temperatures to create new materials with tailored properties. Learn about the melting point of pure copper and its alloys, and how it affects various applications and processes. For instance, when creating brass or bronze, copper is heated to its molten state, and then other elements are added, ensuring a homogeneous mixture. This property ensures that copper components, such as electrical contacts, heat exchangers, and plumbing pipes, can withstand operational temperatures without structural degradation, making it a reliable choice for demanding environments.

Comparing Copper's Melting Point with Other Metals

To truly appreciate the significance of copper's melting point, it's helpful to compare it with other common metals, alloys, and materials. This comparison provides context and highlights why copper is chosen for specific applications over alternatives. You can find the melting point of copper and other common metals, alloys, and materials in various reference sheets.

For instance, aluminum, another widely used conductor, has a significantly lower melting point of 660°C. This difference is particularly relevant in scenarios involving overheating. Copper has a higher melting point than aluminum, so copper’s usually not damaged in situations where aluminum might be. If aluminum is overheated past its 660°C melting point, copper may melt too, but only if the temperature reaches over 1100°C. This substantial gap in melting points is why copper is often preferred in applications where higher temperatures are anticipated, such as heavy-duty electrical wiring or certain industrial furnaces.

Compare the melting points of copper with other metals and explore different methods of melting copper. For example, lead melts at a mere 327.5°C, and tin at 231.9°C, making them suitable for soldering but entirely inappropriate for high-temperature electrical or structural components. Iron, on the other hand, has a melting point of approximately 1538°C, higher than copper, making it suitable for even more extreme thermal conditions, though it lacks copper's superior conductivity. This comparative analysis underscores copper's unique position as a material that balances excellent conductivity with a robust thermal resistance.

Melting Copper: Methods and Considerations

Given its relatively high melting point, melting copper requires substantial energy and specialized equipment. While the "Data Kalimat" doesn't detail specific methods, understanding the general approaches is part of exploring different methods of melting copper. Common methods include:

- Induction Melting: This is a highly efficient method where an electromagnetic field is used to generate heat directly within the copper itself. It allows for precise temperature control and minimizes contamination.

- Crucible Furnaces: These furnaces use a crucible, typically made of refractory materials like graphite or silicon carbide, to hold the copper. Heat is applied externally, often by gas, oil, or electric resistance, to melt the metal within the crucible.

- Arc Furnaces: For larger scale operations, electric arc furnaces can be used. These generate intense heat from an electric arc between electrodes and the metal, capable of reaching very high temperatures quickly.

Regardless of the method, the goal is to uniformly bring the copper to its melting point while controlling impurities and minimizing energy consumption. The choice of method often depends on the volume of copper to be melted, the desired purity, and the specific application of the molten metal.

Safety First: Working with Molten Copper

Working with molten copper, or any molten metal, presents significant hazards due to the extreme temperatures involved. It is crucial to prioritize safety to prevent severe injuries. Compare copper's melting point with other metals and get safety tips for working with molten copper. At 1084°C (1983°F), molten copper can cause instant, severe burns upon contact.

Key safety precautions include:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including heat-resistant gloves, protective eyewear (face shield), heavy-duty aprons or jackets, and safety boots. Molten metal splashes are a serious risk.

- Ventilation: Ensure adequate ventilation to disperse fumes and gases that may be released during the melting process.

- Dry Materials: Any moisture coming into contact with molten metal can cause a violent steam explosion. Ensure all tools, molds, and materials are completely dry before introduction. This is a critical safety consideration.

- Controlled Environment: Work in a designated area with proper fire suppression equipment readily available.

- Training: Only trained and experienced personnel should handle molten copper. Understanding the properties of the metal and the equipment is paramount.

- Emergency Procedures: Have clear emergency procedures in place, including first aid for burns and protocols for containing spills.

Adhering to these safety guidelines is not merely a recommendation but a necessity to protect workers and maintain a safe operational environment when dealing with the intense heat required to reach the copper melting point.

Conclusion: The Unyielding Nature of Copper

The copper melting point, consistently around 1084°C (1983°F) at standard pressure, is a defining characteristic that underpins its extensive utility across numerous industries. From its fundamental role as an excellent electrical and thermal conductor to its resilience in high-temperature applications like welding and alloy production, copper's thermal stability is invaluable. We've explored how factors such as alloy composition, impurities, and environmental conditions like altitude and pressure can subtly influence this critical temperature, emphasizing the need for precision in material science and engineering.

Comparing copper's melting point with other common metals further highlights its unique balance of properties, making it a preferred choice where both conductivity and thermal resistance are paramount. Moreover, the discussion on safety when handling molten copper underscores the significant hazards involved and the absolute necessity of stringent precautions. Understanding the copper melting point is not just about knowing a number; it's about comprehending a fundamental property that dictates how this ancient yet ever-relevant metal shapes our modern world.

We hope this comprehensive article has shed light on the fascinating world of copper and its thermal properties. Do you have any experiences working with molten copper, or perhaps questions about specific applications? Share your thoughts in the comments below! If you found this information valuable, consider sharing it with others who might benefit, and explore our other articles for more insights into materials science and engineering.

Copper | Uses, Properties, & Facts | Britannica

Copper – The Element We can Count on : Chemical Industry Digest

Chemical Elements - Copper